https://player.vimeo.com/video/670138203

Type of tool: Web aplication

Required skills:

- Knowledge of material properties

- No programming or data science knowledge needed

Short description of the tool:

Matrix Tool increases the use of recycled plastic material (recyclate) by matching converter requirements with recyclate supply.

Before you get started, take a look at the :guidelines and make yourself familiar with how to use the tool.

and make yourself familiar with how to use the tool.

Disclaimer:

The Di-Plast project team is not responsible for the consequences of the incorrect application of the content.

How to access it:

The tool is available at https://matrix.sis.cs.uos.de/login.xhtml .

.

Use case/problem:

The tool helps selecting material (recyclate) for specific product requirements. Converters can put their desired specifications (polymer type, processing technology, properties etc.) in the tool. The tool will search the current recyclate supply for for exact matches. If no exact matches exist in the current database, the tool will use an algorithm to recommend alternative recyclates which do not exactly match the filled in specifications. The algorithm includes expert knowledge and could find suitable recyclate batches, which do not exactly fit the filled-in specifications. Additionally, a separate tab on the web-based tool shows the current demand for recyclate batches with a specified set of properties that has not been resolved yet. This information can be used by suppliers in order to sell their recyclate more targeted. Furthermore, this information can be used by suppliers to modify their materials to these specifications.

Description of the problem the tools solves:

European Commission has the goal of reaching a circular economy and plastics have a crucial role in reaching this goal. Plastics are used in many sectors such as packaging, building and construction, textiles, consumer products, transportation, electrical and electronics, and so on. Thus it is important to close the plastic loop to reach a sustainable and resource-efficient economy. One of the ways of achieving the goal is to use recyclate (recycled plastic) as an alternative to the virgin material for new plastic products. Although there is a high demand for recyclate material in the market, a very small amount of product is made from recyclate. This indicates the presence of some challenges in the uptake of the recyclate. Therefore, the main goal of the Interreg Di-Plast project was to increase the uptake of recyclate among the companies.

The Matrix Tool was developed for this purpose. The tool works in two directions. Firstly, it allows converters to easily select the material that matches their process or product requirements. Secondly, it allows recyclate suppliers to make their materials easier to find. Additionally, the recyclate suppliers can check on the demand for batches with a specific set of properties to sell their material in a more targeted way. The advantages of the tool are illustrated in the following figure.

|

Related tools:

- Analyse and Visualize your process data with data analytics -> Data Analytics

- Get guidance to set up a working data infrastucture -> Data Infrastructure Wiki

- Find the right sensor to survey your process -> Sensor Tool

- Improve internal information and material flow -> VSM

Explaination of commonly used material properties#

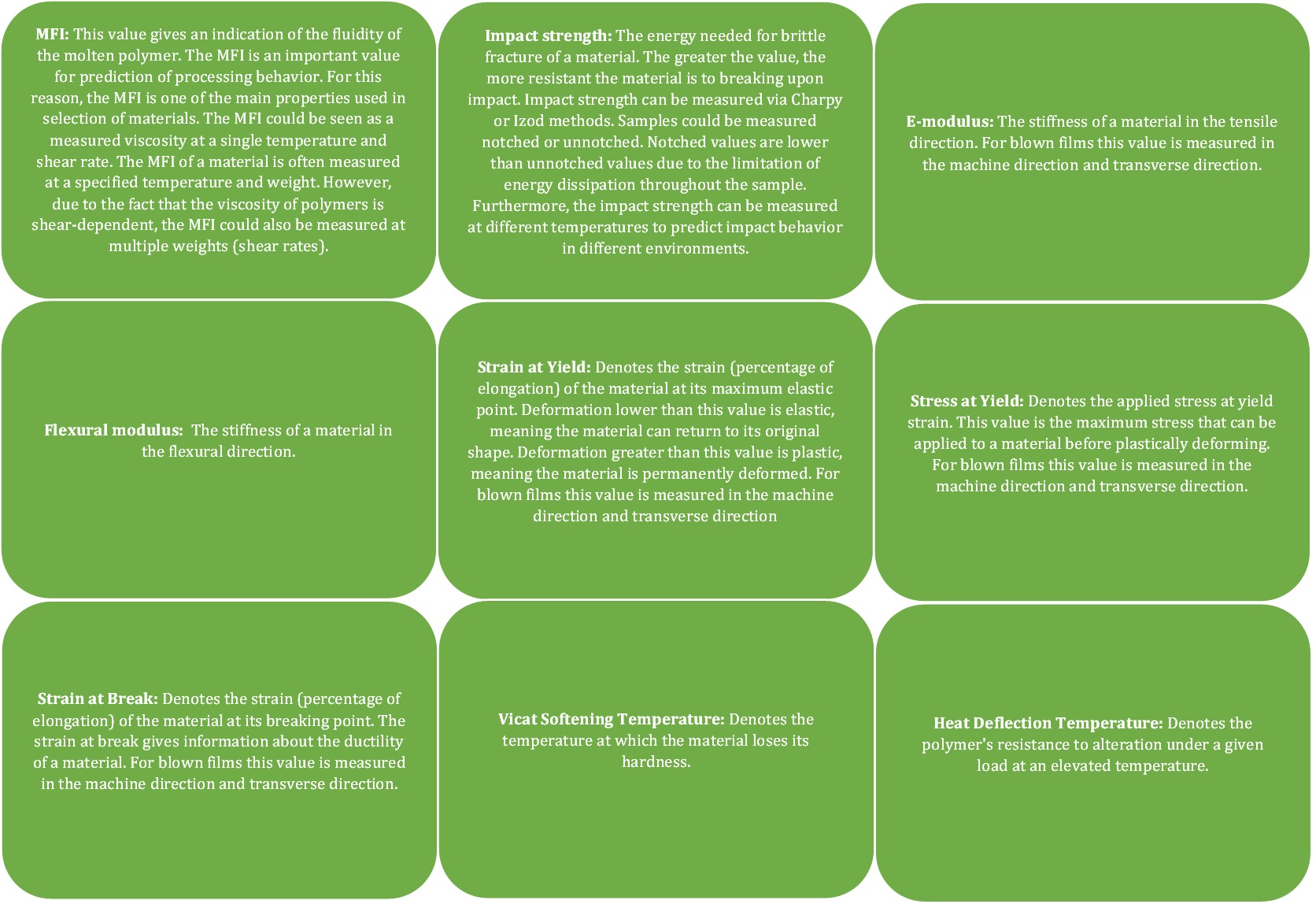

MFI: This value gives an indication of the fluidity of the molten polymer. The MFI is an important value for prediction of processing behaviour. For this reason, the MFI is one of the main properties used in selection of materials. The MFI could be seen as a measured viscosity at a single temperature and shear rate. The MFI of a material is often measured at a specified temperature and weight. However, due to the fact that the viscosity of polymers is shear-dependent, the MFI could also be measured at multiple weights (shear rates).

Impact strength: The energy needed for brittle fracture of a material. The greater the value, the more resistant the material is to breaking upon impact. Impact strength can be measured via Charpy or Izod methods. Samples could be measured notched or unnotched. Notched values are lower than unnotched values due to the limitation of energy dissipation throughout the sample. Furthermore, the impact strength can be measured at different temperatures to predict impact behavior in different environments.

E-modulus: The stiffness of a material in the tensile direction. For blown films this value is measured in the machine direction and transverse direction.

Flexural modulus: The stiffness of a material in the flexural direction.

Strain at yield: Denotes the strain (percentage of elongation) of the material at its maximum elastic point. Deformation lower than this value is elastic, meaning the material can return to its original shape. Deformation greater than this value is plastic, meaning the material is permanently deformed. For blown films this value is measured in the machine direction and transverse direction.

Strength at yield: The applied stress at yield strain. This value is the maximum stress that can be applied to a material before plastically deforming. For blown films this value is measured in the machine direction and transverse direction.

Strain at break: This value denotes the strain (percentage of elongation) of the material at its breaking point. The strain at break gives information about the ductility of a material. For blown films this value is measured in the machine direction and transverse direction.

Vicat softening temperature: Denotes the temperature at which the material loses its hardness.

Heat deflection temperature: It is a measure of a polymer's resistance to alteration under a given load at an elevated temperature.